SMART DISTANCE METER.

CHAPTER ONE

1.0

INTRODUCTION

Measuring

a distance by using a smart meter is greet for use now day. In construction and

for domestic usage, the measurement is from tape meter and other distance

measure equipment. Distance Measurement using microcontroller and Ultrasonic

Sensor. The ultrasonic sensor is consisting of Transmitter and Receiver

modules. Transmitter part ejects the pulse out and the receiver part receives

the pulse. If an obstacle is placed before the sensor, the transmitted

pulse ejected strike the obstacle and reflected back. The reflected pulse

is received by the receiver part. The time between transmission and reception

is calculated. This data is processed to calculate distance

1.1

Background

This

project implemented the ultrasonic sensor. Ultrasonic technology is one of the

solutions used to optimized balance between cost and the device features. The

ultrasonic distance measurer is used 'mainly when a non-contact measurer is

required. The Smart Distance Measurement Detector using ATMEGA 328P is an

efficient way to measure distance and check measurement value that is stored in

memory, where the device can record and recall distance measurements, 'allowing

several readings to be taken before copying them into paper.

1.2

PROBLEM STATEMENT

In

the construction field, the usage of electronic measuring device is still not

widely used yet. Due to the high cost of these equipment’s at market, an

economic way needs to think of in order to create an accurate measuring device

with low cost. Nowadays, measuring distance is considered as problem in

construction field or indoor measuring activities because this task is made by

using measuring tape. The problem will occur when using measuring tape where we

need at least 2 persons to measure between two distances. Besides, it is not

having a perfect accuracy due to parallax and obstacle in their way.

Therefore,

this project is necessary to do the process of measurement quickly and accurate

without doing measurement manually, it also has the advantages to store

measurement as many as 32 memories at one time.

1.2.1 Main

objective

The

main objective of this project is to minimize/reduce/eliminate parallax error,

calibration error and using long time to get reading.

1.2.2 Specific

objective

To

design an electronics smart distance meter that allows multi activities to take

place in many fields.

To

design an electronics smart distance meter that can save data in MEMORY CARD by

reducing data loss.

1.3

Methodology

On

performing my project, the following methods are used in order to achieve the

objectives of the project.

1.3.1 Literature

review

Under literature review, the reading different

books, consulting lecturers, notes from the class, visiting websites, explain

the features, operations and limitation of both existing system and proposed

system.

1.3.2 Data

collection

The

data were collected from different sources such as web site, domestic keepers,

magazines and radio.

1.3.3 Data

analysis

The

analysis has been done according to the operation of circuit by using different

formulas.

The

circuit has been designed to measure distance.

1.3.5 Simulation

Proteus professional software can have been

used to simulate the circuit in order to determine whether the circuit works or

not.

1.3.6 Building

prototype

The

circuit has been built on PCB board by using physical connection of components

It

was done by comparing the results from simulation and those that has been

observed after building the circuit.

1.3.8

Report writing

This involves preparation of the report book to include all activities conducted in first semester and second semester such as literature review, data collection, data analysis, designing, simulation, building, testing and report writing.

CHAPTER TWO

2.0 LITERATURE

REVIEW

2.1 The existing system:

This project is to design and create a better distance better distance measurement that can encounter the measuring problem. An ultrasonic measuring device is proposed to solve the problem as the ultrasonic using an ultrasonic sound. The ultrasonic transducer is operating at frequencies in between 40 kHz to 250 kHz. The concept for the project is using the LCD screen and displayed the reading of distance measured2.1.1 Disadvantages of existing

system

Reading obtained from the field can’t be used for feature

because haven’t stored.

2.2 Proposed system

for

the project is using the LCD screen and displayed the reading of

distance measured and user can save measurement to memory card for future uses.

2.2.1 Advantages of proposed system

- Save time to take measurement.

- Reduce/ eliminate/minimize the parallax and obstacle in their way.

- Allow multi activities to take place in distance measurement.

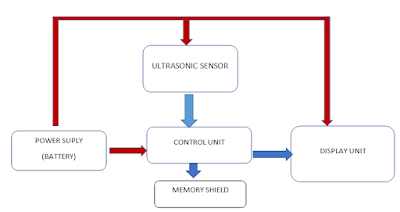

2.3 BLOCK DIAGRAM OF THE

PROPOSED SYSTEM

Figure 2: The block diagram of the proposed system

2.4

ULTRASONIC SENSOR

Ultrasonic

(US) sensors are also widely used to measure distances. Thus, they have

provided a reliable source of obstacle detections. Since they are not vision

based, they are useful under conditions of poor lighting and transparent

objects. However, ultrasonic sensors have limitations due to their wide

beam-width, sensitivity to specular surfaces, and the inability to discern

objects within 0.5 m. Because of the typical specular nature of the ultrasonic wave’s

reflection, only reflecting objects that are almost normal to the sensor

acoustic axis may be accurately detected. Most ultrasonic sensors use a single

transducer to both transmit the sound pulse and receive the reflected echo,

typically operating at frequencies between 40 kHz and 250 kHz. A variety of

different types of transducers are used in these systems. Ultrasonic is one of

the distances measuring sensors that had been studied.

Ultrasonic transducers measure the amount of

time taken for a pulse of sound to travel to a particular surface and return as

the reflected echo Typically, an b ultrasonic rangefinder sends a 'ping' and

waits to hear an echo. Sound waves propagate from the transmitter and bounce

off objects, returning an echo to the receiver (below left). If the speed of

sound is known, the distance to an object can be calculated from the time delay

between the emitted and reflected sounds. While the principle of calculating

distance from the time of travel is simple, there are many limiting factors to

consider. Sound diverges very rapidly, so transducers are carefully designed to

produce as small a beam as possible. While some applications require a wide

beam, a narrow beam improves the range and reduces background interference.

There is a direct relationship between beam width and target surface angle: the

wider the beam, the greater the possible angle between the transducer and the

surface. When the angle is too great (>12 degrees), the reflected beam

misses the transducer as Figure 2. While some surfaces may produce scattered

diffuse reflections, these are much weaker and are not used for distance

measuring purposes.

Figure 3: The ultrasonic sensor

2.5

PROPOSED CIRCUIT DIAGRAM

Figure 4: The proposed circuit diagram of system.

2.5.1 General operation of the proposed circuit system

The

operation of the system depends on changes of temperature. The 9V DC voltage is

used to energize the smart distance meter system. This system employs the use

of ultrasonic sensor as distance sensing device. It works on the principle that

Distance Measurement using microcontroller and Ultrasonic Sensor. The

ultrasonic sensor is consisting of Transmitter and Receiver modules.

Transmitter part ejects the pulse out and the receiver part receives the pulse.

If an obstacle is placed before the sensor, the transmitted pulse ejected

strike the obstacle and reflected back. The reflected pulse is received by

the receiver part. The time between transmission and reception is calculated.

This data is processed to calculate distance.

CHAPTER THREE

3.0 DATA COLLECTION

In accomplishing the project data were

collected from different sources apart from internet Browsing and reading different books

data were also collected from circuit components.

3.1Circuit

components

Table 1: Specification of components.

|

|

COMPONENTS |

DESCRIPTIONS |

QUANTITIES |

COST |

|

1 |

BATTERY |

9V |

2 |

4000/= |

|

2 |

VOLTAGE

REGURATORY |

LM7805 |

1 |

2000/= |

|

3 |

TERMINAL

BLOCK |

2

HOLES |

4 |

2000/= |

|

4 |

ARDUINO

CONNECTOR |

20

HOLES |

4 |

4000/= |

|

5 |

Variable

resistor |

10kΏpotentiometer |

1 |

500/= |

|

6 |

Liquid

crystal display |

16x2 |

1 |

15000/= |

|

7 |

I2C

|

MODULE |

1 |

10000/= |

|

8 |

MICROCONTROLLER

IC |

ATMEGA

328P |

1 |

15000/= |

|

9 |

CLYSTAL

OSCILLATOR |

16KHZ |

1 |

2000/= |

|

10 |

CAPACITOR |

1000Uf,22pf,100nf |

@2 |

3000/= |

|

|

COMPONENTS |

DESCRIPTIONS |

QUANTITIES |

COST |

|

11 |

IC

BASE |

28

PIN |

1 |

1000/= |

|

12 |

UTRASONIC

SENSOR |

HC-SRO4 |

1 |

15000/= |

|

13 |

MEMORY

CARD READER |

MODULE |

1 |

15000/= |

|

14 |

WATER

PROOF BOX |

150mm

*130mm |

1 |

15000/= |

|

15 |

SOLDER

WIRE |

COPPER |

20m |

10000/= |

|

16 |

JUMPER

WIRE |

RED,

BLUE, BLACK, ORRANG |

30 |

3000/= |

3.2 Key Formulas

To

measure the distance the sound has traveled we use the formula:

Distance

= (Time x Speed Of Sound) / 2.

The

"2" is in the formula because the sound has to travel back and forth.

First, the sound travels away from the sensor, and then it bounces off of a

surface and returns back.

3.3 The Distance

that can measure.

3.3.1 Distance at surface level 2cm

– 450cm

3.3.2 Distance deep to the ground 2cm-

350cm

4.0 REFERENCES

Electronics Principles and Application 5th

edition By Charles A. Schuler.

“Electronics

Principles”. Sixth Edition,

Albert Malvino, 1999, by Glencoe McGraw-hill Companies.

0 Comments